The adaptability of a wastewater centrifuge can be attributed to the many configurations and applications for which it is suited. From microcentrifuges that are used in genetic testing to heavy-duty machines for industrial processing, each is optimized for a particular purpose. The latest versions usually come with wireless monitoring systems, whose real-time data tracking occurs through mobile interfaces. Improved rotor materials allow for higher strength and corrosion resistance. In addition, automated calibration systems reduce maintenance time while improving consistency in performance. With these advancements, the wastewater centrifuge is a vital instrument in the continued search for scientific precision and efficiency.

wastewater centrifuge technology is a principal component in diverse manufacturing processes. In wastewater treatment, wastewater centrifuge assist in separating sludge from liquids to improve recycling efficiency. In the manufacture of cosmetics, wastewater centrifuge facilitate even emulsion and cream mixing. Crop research facilities apply it to analyze soil nutrients and plant extracts. It is also used in the manufacture of vaccines through the purification of viral particles and protein fractions. Through the ability to adapt to many substances and work requirements, wastewater centrifuge continues to support industries seeking consistency, purity, and scalability.

wastewater centrifuge will integrate digital intelligence and cutting-edge engineering in the years to come. Complex algorithms will auto-tune parameters for optimum efficiency and safety. Energy-optimized designs will keep operating costs at a minimum and help support global green efforts. Robotics integration will facilitate round-the-clock unattended operation in big production setups. Modular design will provide ease of customization, allowing users to set up wastewater centrifuge for specific scientific or industrial uses. These improvements will allow wastewater centrifuge to not only increase performance but also establish new standards for automation, accuracy, and sustainability in the lab environments of the future.

Continuous cleaning and routine checkup maintain a wastewater centrifuge in good working order. The rotor must be carefully inspected for distortion or corrosion because even small flaws can result in unbalance. Users should clean the interior chamber with a soft cloth at the end of each run to remove residues. Electrical and mechanical components must undergo regular checks for proper alignment and accuracy of speed. Periodic calibration at specified intervals maintains measurement precision. By implementing a formal maintenance regime and strict compliance with manufacturer instructions, the wastewater centrifuge is dependable upon repetitive application.

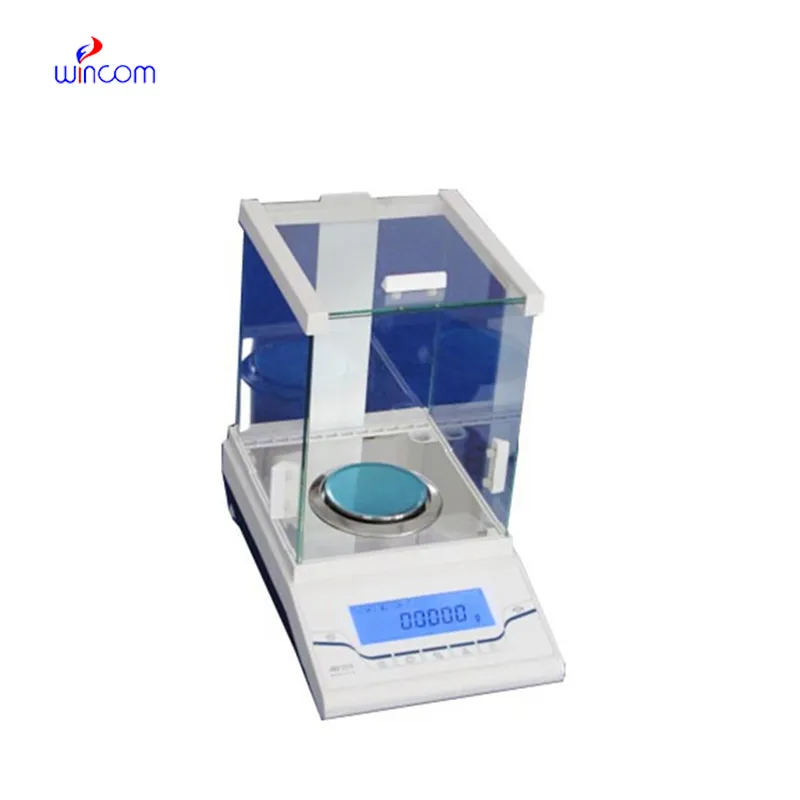

A wastewater centrifuge operates by inducing centrifugal force through rapid rotation, separating substances according to mass and density. It has a critical use in laboratories, medical testing, and industrial treatment. In medicine, for instance, wastewater centrifuge facilitate plasma and serum separation for the purpose of diagnosis. In environmental science, they assist in the examination of suspended solids in water samples. Their robust build, combined with programmable functions and safeguarding features, facilitates fine speed control and timing. wastewater centrifuge continue to evolve to provide faster and more accurate separation procedures in various fields.

Q: What is a centrifuge used for? A: A centrifuge is used to separate mixtures based on density differences by spinning them at high speeds, allowing heavier particles to settle away from lighter ones. Q: How does a centrifuge work? A: A centrifuge operates by generating centrifugal force, pushing denser materials outward while lighter components remain near the center, resulting in effective separation. Q: What are common applications of a centrifuge? A: Centrifuges are used in laboratories, hospitals, and industries for blood testing, chemical analysis, purification, and sample preparation. Q: How often should a centrifuge be calibrated? A: Calibration should be performed at least once a year or whenever performance inconsistencies appear to ensure accuracy and reliability. Q: Can a centrifuge handle biological samples? A: Yes, many centrifuges are designed for biological materials such as blood, plasma, and cell cultures under controlled and sterile conditions.

This ultrasound scanner has truly improved our workflow. The image resolution and portability make it a great addition to our clinic.

This x-ray machine is reliable and easy to operate. Our technicians appreciate how quickly it processes scans, saving valuable time during busy patient hours.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We’re interested in your delivery bed for our maternity department. Please send detailed specifica...

Hello, I’m interested in your centrifuge models for laboratory use. Could you please send me more ...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China