The operation of an centrifuge force largely relies on its rotor design, accuracy in balancing, and operating speed. Modern models typically come with programmable interfaces that allow users to control acceleration rates, temperature, and run times with great accuracy. Some advanced centrifuge force incorporate vibration sensing and auto-imbalances for stabilizing high-speed rotation. Additionally, the use of light but strong materials like carbon fiber enhances safety and energy efficiency. This marriage of engineering ingenuity and electronic control combines the centrifuge force into a reliable partner for research and production environments.

The diversity of centrifuge force applications shows its diversity to modern technology. Aerospace engineers utilize it to check the material properties under intense centrifugal stress. Nanotechnology utilizes it to segregate particles at micro and nanolevel for analysis and manufacturing purposes. Hospitals rely on centrifuge force for testing, ensuring accurate plasma and serum analysis. Food processing industries utilize it to ensure product purity and uniformity. Additionally, educational laboratories employ centrifuge force in teaching and experimentation, whereby students learn fundamental physics, chemistry, and biology concepts through hands-on demonstration.

Future development of centrifuge force will focus on precision control and data integration. Next-generation models will have sophisticated sensors that log every parameter of operation, generating total digital records for traceability. Performance trends will be predicted using machine learning, providing repeatable results. Hybrid centrifuge force systems that can perform solid-liquid-gas separations will become a reality. Better safety designs and noiseless operation will make them easier to use. As research demands grow, these intelligent, automated centrifuge force will be at the center of labs, enabling faster discovery and industrial productivity globally.

For optimal performance, centrifuge force equipment needs to be handled cautiously and carefully. Operators need to ensure that rotors are balanced before use to avert vibration and wear. Regular cleaning of inner and outer surfaces prevents residues from building up that can impact results. Electric wiring should be inspected for loose or damaged cables. Storage of centrifuge force in a clean, temperature-controlled environment keeps its components. Regular professional maintenance and replacement of worn parts on schedule ensure smooth and efficient use of the device over time.

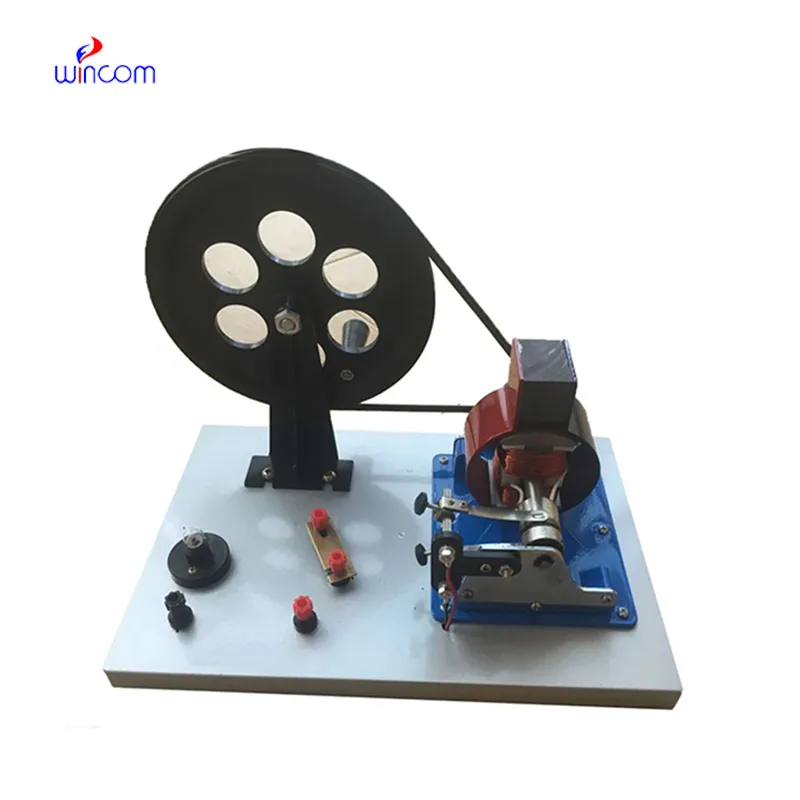

A centrifuge force operates by inducing centrifugal force through rapid rotation, separating substances according to mass and density. It has a critical use in laboratories, medical testing, and industrial treatment. In medicine, for instance, centrifuge force facilitate plasma and serum separation for the purpose of diagnosis. In environmental science, they assist in the examination of suspended solids in water samples. Their robust build, combined with programmable functions and safeguarding features, facilitates fine speed control and timing. centrifuge force continue to evolve to provide faster and more accurate separation procedures in various fields.

Q: What are the main components of a centrifuge? A: Key components include the rotor, motor, control panel, safety lid, and chamber, each working together to achieve precise separation. Q: How can I verify that a centrifuge is functioning correctly? A: Check that the machine runs smoothly without any unusual vibrations or noises, check the speed accuracy and evaluate the results to ensure consistent separation. Q: Is it safe to open a centrifuge immediately after use? A: No, the device should come to a complete stop before opening to avoid injury or sample disruption. Q: How should a centrifuge be stored when not in use? A:Store it unplugged, covered, and in a dry, dust-free environment to protect internal components from moisture and corrosion. Q: Can centrifuge operation be automated? A: Yes, modern models include programmable controls and digital interfaces that allow automated speed, time, and temperature settings.

The microscope delivers incredibly sharp images and precise focusing. It’s perfect for both professional lab work and educational use.

We’ve used this centrifuge for several months now, and it has performed consistently well. The speed control and balance are excellent.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Hello, I’m interested in your centrifuge models for laboratory use. Could you please send me more ...

Hello, I’m interested in your water bath for laboratory applications. Can you confirm the temperat...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China