Emerging technologies have driven the performance boundaries of the centrifuge cost, offering improved acceleration rates and greater throughput of samples. Programmable features and touchscreens give users more control over every operation stage. Temperature-controlled centrifuge cost in delicate biological processes guarantee specimen stability over extended cycles. Maintenance-friendly designs and auto-diagnostic programs minimize downtime. The adaptability of next-generation centrifuge cost devices ensures compatibility with any sample type, ranging from microfluidic volumes to industrial suspensions, making it a vital tool in scientific and engineering studies.

Across different industries, centrifuge cost machinery is a necessity in maintaining process effectiveness. In biotechnology, they are required for cell harvesting and sample preparation prior to downstream analysis. {Keywords} are used by petroleum refineries to separate impurities from lubricants and fuels. Dairy manufacture utilizes their ability to correctly separate cream from milk. Forensic science utilizes centrifuge cost to analyze biological samples with accuracy. Their ability to work with liquids, suspensions, and emulsions of varying densities places them in any setting requiring uniform and repeatable material separation.

{Keywords} in the future will evolve into fully networked instruments in smart laboratories. They will "communicate" with other analytical instruments through built-in digital platforms, making experimental workflows easier. Equipped with self-diagnostic systems, maintenance needs will be identified before any issues arise. Future centrifuge cost models will emphasize energy efficiency and portability without compromising on speed or accuracy, while integration with robotics, AI-driven optimization, and user-friendly interfaces will redefine operations standards. In production and research environments, centrifuge cost will play a key role in achieving higher productivity and sustainable performance.

For optimal performance, centrifuge cost equipment needs to be handled cautiously and carefully. Operators need to ensure that rotors are balanced before use to avert vibration and wear. Regular cleaning of inner and outer surfaces prevents residues from building up that can impact results. Electric wiring should be inspected for loose or damaged cables. Storage of centrifuge cost in a clean, temperature-controlled environment keeps its components. Regular professional maintenance and replacement of worn parts on schedule ensure smooth and efficient use of the device over time.

A centrifuge cost operates by inducing centrifugal force through rapid rotation, separating substances according to mass and density. It has a critical use in laboratories, medical testing, and industrial treatment. In medicine, for instance, centrifuge cost facilitate plasma and serum separation for the purpose of diagnosis. In environmental science, they assist in the examination of suspended solids in water samples. Their robust build, combined with programmable functions and safeguarding features, facilitates fine speed control and timing. centrifuge cost continue to evolve to provide faster and more accurate separation procedures in various fields.

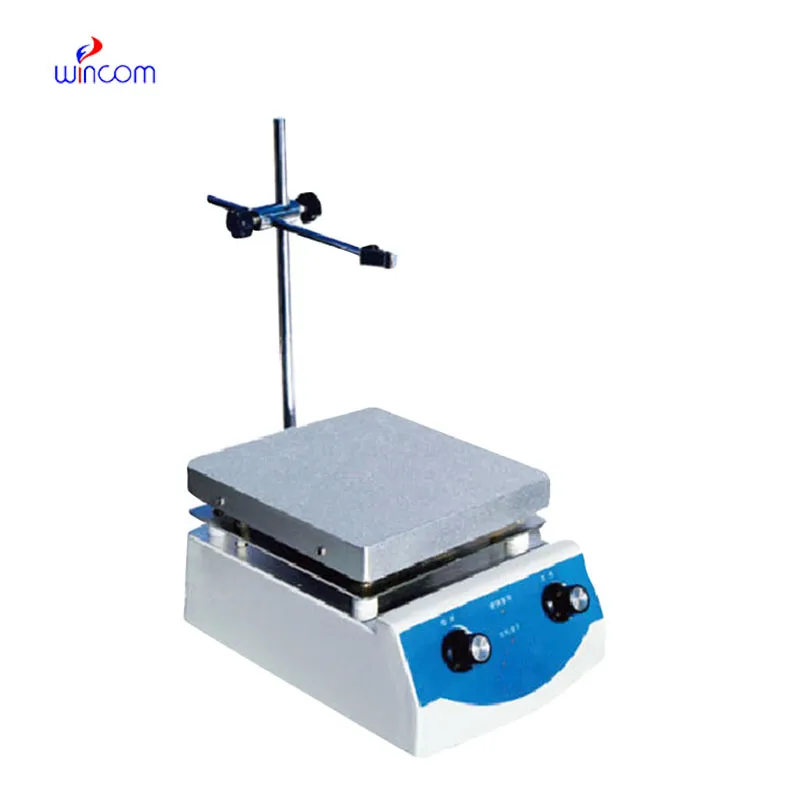

Q: What are the main components of a centrifuge? A: Key components include the rotor, motor, control panel, safety lid, and chamber, each working together to achieve precise separation. Q: How can I verify that a centrifuge is functioning correctly? A: Check that the machine runs smoothly without any unusual vibrations or noises, check the speed accuracy and evaluate the results to ensure consistent separation. Q: Is it safe to open a centrifuge immediately after use? A: No, the device should come to a complete stop before opening to avoid injury or sample disruption. Q: How should a centrifuge be stored when not in use? A:Store it unplugged, covered, and in a dry, dust-free environment to protect internal components from moisture and corrosion. Q: Can centrifuge operation be automated? A: Yes, modern models include programmable controls and digital interfaces that allow automated speed, time, and temperature settings.

The centrifuge operates quietly and efficiently. It’s compact but surprisingly powerful, making it perfect for daily lab use.

We’ve been using this mri machine for several months, and the image clarity is excellent. It’s reliable and easy for our team to operate.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

Hello, I’m interested in your water bath for laboratory applications. Can you confirm the temperat...

We are planning to upgrade our imaging department and would like more information on your mri machin...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China