A centrifugal fans and blowers is based on a combination of speed, pressure, and design geometry. The development of more advanced rotor designs has optimized airflow and reduced heat generation when operating. Programmable memory is featured in most systems, allowing users to store frequently used parameters to maximize efficiency. Additionally, power-saving motors and sound-dampening enclosures minimize lab discomfort. The ability to spin micro and macro volumes with the same reproducibility gives centrifugal fans and blowers equipment an edge both in the research and industrial settings. As technology advances, it remains to be at the forefront of precision and productivity.

The utilitarian uses of centrifugal fans and blowers have expanded due to technological advancements. It is utilized in pharmacology to ensure high-purity drug formulations. It is utilized in biotechnology for protein crystallization and vaccine synthesis. The extractive industry utilizes centrifugal fans and blowers to separate valuable minerals from raw mixture. In classrooms, it facilitates laboratory demonstrations of fluid flow. Even in the restoration of paintings, expert centrifugal fans and blowers facilitate cleaning and stabilizing delicate pigments. The applicability of centrifugal fans and blowers to so many different fields is evidence of its utility as an industrial and scientific agent for material separation.

Advances in automation and material science will shape the future of centrifugal fans and blowers. Composite lightweight materials will offer increased speed and reduced mechanical stress. Integrated AI controls will streamline rotor performance and balance in real time. The addition of remote operation and touchless interfaces will increase accessibility in sterile environments. As data-driven laboratories expand, centrifugal fans and blowers will be connected to cloud-based systems for predictive diagnostics and performance analytics. All these innovations will create a new generation of smart instruments with the capacity to enable high-throughput, complex applications with precision.

For optimal performance, centrifugal fans and blowers equipment needs to be handled cautiously and carefully. Operators need to ensure that rotors are balanced before use to avert vibration and wear. Regular cleaning of inner and outer surfaces prevents residues from building up that can impact results. Electric wiring should be inspected for loose or damaged cables. Storage of centrifugal fans and blowers in a clean, temperature-controlled environment keeps its components. Regular professional maintenance and replacement of worn parts on schedule ensure smooth and efficient use of the device over time.

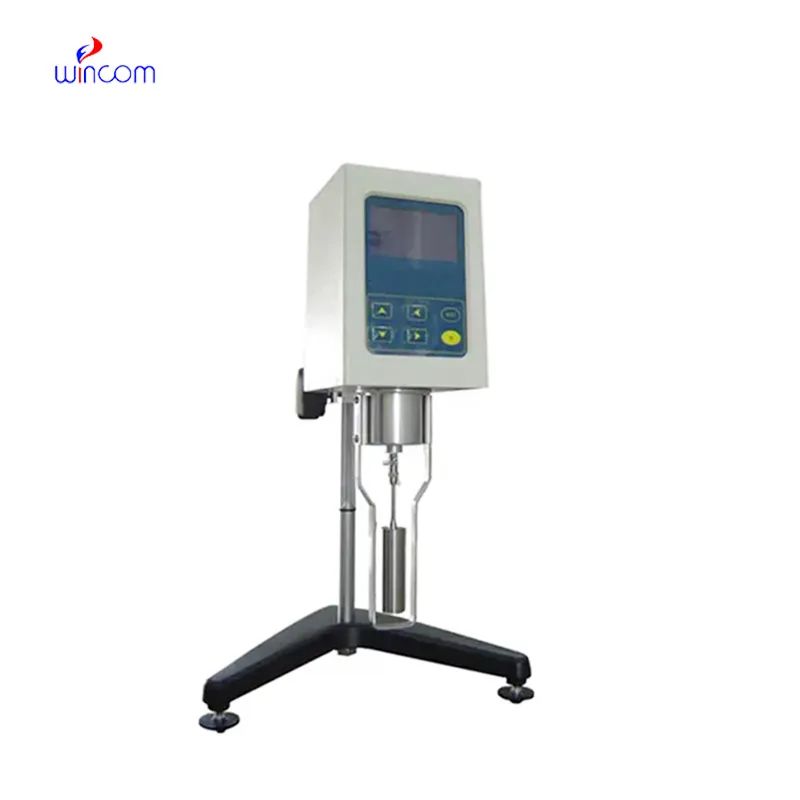

A centrifugal fans and blowers operates by inducing centrifugal force through rapid rotation, separating substances according to mass and density. It has a critical use in laboratories, medical testing, and industrial treatment. In medicine, for instance, centrifugal fans and blowers facilitate plasma and serum separation for the purpose of diagnosis. In environmental science, they assist in the examination of suspended solids in water samples. Their robust build, combined with programmable functions and safeguarding features, facilitates fine speed control and timing. centrifugal fans and blowers continue to evolve to provide faster and more accurate separation procedures in various fields.

Q: What are the main components of a centrifuge? A: Key components include the rotor, motor, control panel, safety lid, and chamber, each working together to achieve precise separation. Q: How can I verify that a centrifuge is functioning correctly? A: Check that the machine runs smoothly without any unusual vibrations or noises, check the speed accuracy and evaluate the results to ensure consistent separation. Q: Is it safe to open a centrifuge immediately after use? A: No, the device should come to a complete stop before opening to avoid injury or sample disruption. Q: How should a centrifuge be stored when not in use? A:Store it unplugged, covered, and in a dry, dust-free environment to protect internal components from moisture and corrosion. Q: Can centrifuge operation be automated? A: Yes, modern models include programmable controls and digital interfaces that allow automated speed, time, and temperature settings.

The water bath performs consistently and maintains a stable temperature even during long experiments. It’s reliable and easy to operate.

We’ve been using this mri machine for several months, and the image clarity is excellent. It’s reliable and easy for our team to operate.

To protect the privacy of our buyers, only public service email domains like Gmail, Yahoo, and MSN will be displayed. Additionally, only a limited portion of the inquiry content will be shown.

We’re looking for a reliable centrifuge for clinical testing. Can you share the technical specific...

Could you please provide more information about your microscope range? I’d like to know the magnif...

E-mail: [email protected]

Tel: +86-731-84176622

+86-731-84136655

Address: Rm.1507,Xinsancheng Plaza. No.58, Renmin Road(E),Changsha,Hunan,China